General maintenance

Condensation forms inside the silencer during shooting, and this condensation contains ammonia, amongst other compounds. We recommend that the silencer is removed immediately after use, and always before the rifle is packed up for transport.

After use, store the silencer in a warm place where air can flow freely through it to allow any condensation to evaporate.

Spray a little light oil into the silencer when it is dry. Keep the silencer and rifle threads clean and lightly oiled or greased.

Failure to follow maintenance instructions may lead to corrosion that will damage the barrel permanently and weaken components inside the silencer. This may lead to product failure and compromises the safety!

Fitting

The initial fitting of A-TEC silencers should always be carried out by an experienced and competent gunsmith – even if the rifle already has a factory-made muzzle thread. The threads and shoulder must have a smooth surface and must engage with the silencer so that it can be screwed on freely, but without too much noticeable slack before it is screwed tight to the shoulder.

Before fitting the silencer, inspect the threads and the shoulder and make sure that they are smooth, have been properly cleaned, and that the silencer is not damaged in any way. Do not use a mirage cover on the Carbon silencer, as it may cause overheating. The Carbon is a lightweight silencer designed for hunting use and not for long shooting sessions at the range. The approved cartridges are listed at www.a-tec.no. Home-loaded cartridges should be used with caution - and should not be loaded “hotter” than standard cartridges. Pay attention to the temperature stickers whenever you change ammo or powder weight so that you learn to recognize the limits of your hunting rifles and ammunition in combination with the silencer.

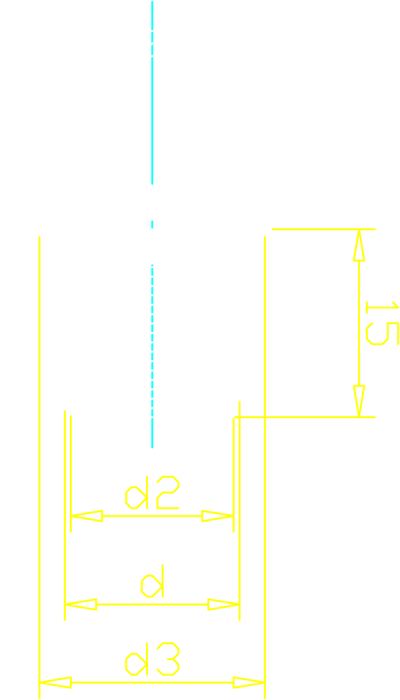

A-TEC silencers are designed for firearms with a 15 mm long thread. The silencer threads are made with a tolerance allowing the desired thread to fit with minimal clearance when the barrel threads have a mid-diameter in accordance with NS 1073 part 6, upper tolerance limit. The barrel threads must have a relief cut at the junction with the shoulder; the maximum radius between the bottom of the undercut and the shoulder is 0.8 mm. The diameter of the undercut must be 0.2 mm less than the minimum diameter of the external thread. The shoulder must be turned with a maximum surface roughness of Ra 1.6. Where supplied, the Delrin bushing must not be tight on the barrel. Recommended clearance is 0.1 mm, and this should be checked when the silencer is fitted to the firearm. The bushing should be bored to fit the barrel by the gunsmith who fits the silencer.

N.B. A-TEC silencers are designed with little clearance between the projectile and the inner diameter, in order to achieve the best possible silencing efficiency. Precise threading of the barrel muzzle is therefore important. The centreline of the silencer must be completely concentric with the barrel axis. The initial fitting of the silencer must be carried out and checked by a qualified and competent gunsmith, to ensure the necessary precision. Damage caused by imprecise fitting of the silencer is not covered by the manufacturer’s warranty.

A list of standard thread dimensions and the minimum recommended diameter of the shoulder at the muzzle is below:

d d3

½”-28 UNEF 14mm

M13x1 14.5mm

M14x1 15.5mm

M15x1 16.5mm

M17x1 18.5mm

M18x1 19.5mm

M14x1.5 16mm

M16x1.5 18mm

M18x1.5 20mm